STRUCTURAL HOLLOW SECTIONS

Structural hollow sections are one of the most versatile and efficient solutions when it comes to metal and composite construction, or even mechanical applications. They are produced according to the EN 10219-1/2 standard, in numerous strength classes according to EC3.

With structural welded hollow sections, it becomes possible to obtain:

- Resistant structures with excellent performance in compression and torsion;

- Lightweight and dynamic structures;

- Large spans;

- Less exposure to corrosion and ease of maintenance;

- High strength-to-weight ratio.

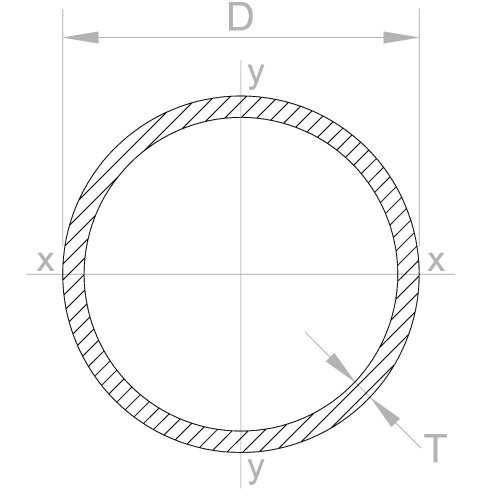

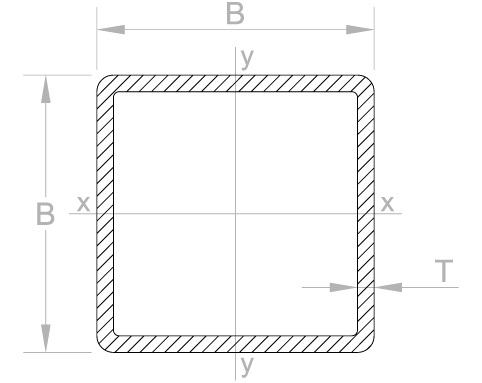

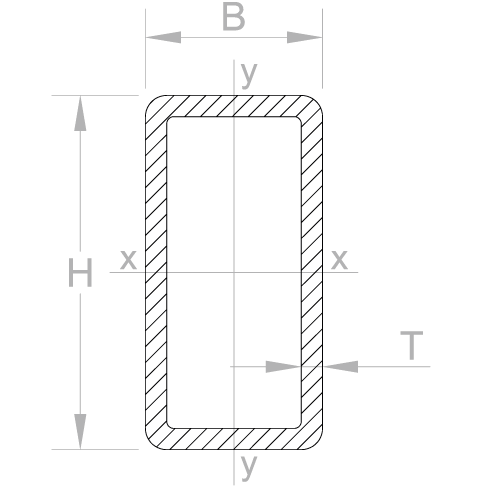

FERPINTA's range of structural hollow sections consists of round, square and rectangular products, longitudinally welded, cold-formed and without subsequent heat treatment.

The tube is supplied in black (rough rolled) and is available in several steel grades.

SUPPLY CONDITIONS

The material is available in geometric ties, strapped with steel bands, in hexagonal, square, and/or rectangular shapes. To facilitate handling (loading/unloading), all the ties are supplied with polyester straps suitable for the weight of the tie.

Each tie is supplied with a label attached by a metal clip, ensuring the identification of the product and consequently its traceability.

During manufacture, all tubes are coated with a protective oil, which has a high hydrophobing power, to protect the surface against corrosion. Unless otherwise stated by the customer at the time of the order/inquiry.

On shipment, all orders are accompanied by the respective inspection certificate according to EN 10204, in accordance with the product’s applicable standard.

SUPPLY OPTIONS

Hot-dip galvanized tubes can be supplied, according to EN 10240 A.1/A.2 or ISO 1461, providing greater protection against corrosion.

Special tolerances must be requested when inquiring/ordering.

Possibility of removing the internal welding bead. Possibility of defining the position of the weld bead, according to target value and/or face of the tube.

Possibility of supplying tubes with chemical properties that guarantee their suitability for hot-dip galvanization.

Possibility to specify the CEV value at the time of inquiry/order.

It is possible to supply tubes that meet the requirements compatible with weldability at the corners according to EC3.

Capacity to supply tubes with specific lengths, requested at the time of inquiry/order.

Tubes can be supplied, according to the most demanding deformation capabilities.

The ties can be configured, according to the client's indications, at the time of the inquiry/order. Possibility of using packaging with anticorrosion protection (VCI).

Possibility of requesting specific laboratory tests, not foreseen in the applicable standard (anisotropy, salt fog, metallography, thickness elongation, among others)

Application

talk to us

If you need to know more or want a contact more suited to your needs, do not hesitate.