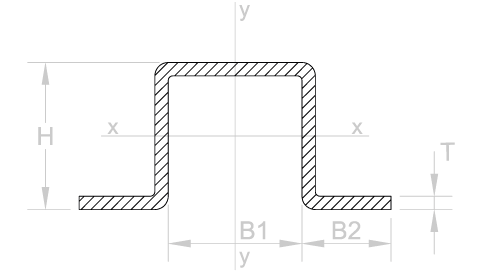

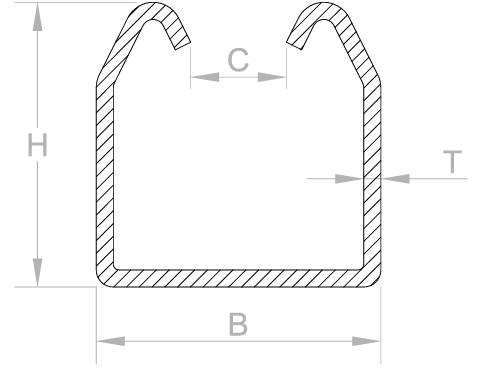

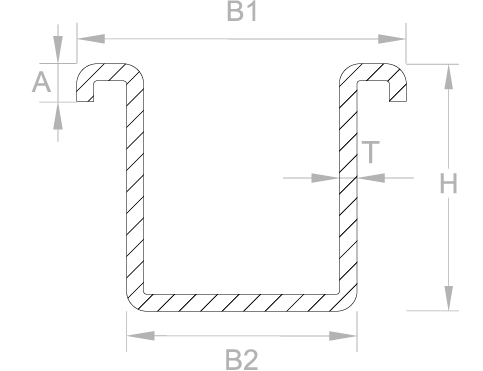

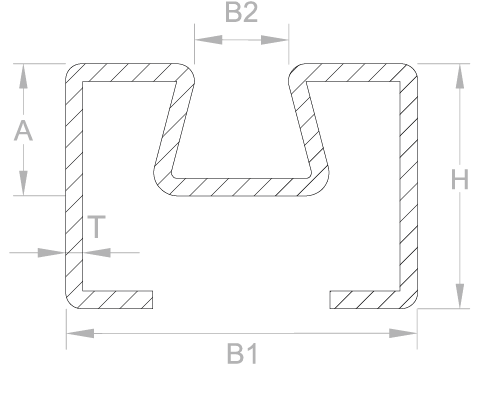

OPEN SECTIONS (Gutters)

Open sections are produced by progressive cold-forming of steel strips.

The various cross sections obtained can be subjected to welding, punching, drilling, etc. This results in a wide field of applications. The technical supply conditions are in accordance with EN 10162.

These sections represent effective solutions in several areas and for different purposes, such as: support for road rails, greenhouses, metallic structures, solar parks, automobile parks, trailer chassis, and in architectural works and engineering solutions.

DX51D , DX52D, DX53D

S250GD, S280GD, S350GD

SUPPLY CONDITIONS

The material is available in geometric ties, strapped with steel bands, in hexagonal, square, and/or rectangular shapes. To facilitate handling (loading/unloading), all the ties are supplied with polyester straps suitable for the weight of the tie.

Each tie is supplied with a label attached by a metal clip, ensuring the identification of the product and consequently its traceability.

During manufacture, all tubes are coated with a protective oil, which has a high hydrophobing power, to protect the surface against corrosion. Unless otherwise stated by the customer at the time of the order/inquiry.

On shipment, all orders are accompanied by the respective inspection certificate according to EN 10204, in accordance with the product’s applicable standard.

SUPPLY OPTIONS

Hot-dip galvanized tubes can be supplied, according to EN 10240 A.1/A.2 or ISO 1461, providing greater protection against corrosion.

Special tolerances must be requested when inquiring/ordering.

Possibility of supplying tubes with chemical properties that guarantee their suitability for hot-dip galvanization.

Possibility to specify the CEV value at the time of inquiry/order.

Capacity to supply tubes with specific lengths, requested at the time of inquiry/order.

Tubes can be supplied, according to the most demanding deformation capabilities.

The ties can be configured, according to the client's indications, at the time of the inquiry/order. Possibility of using packaging with anticorrosion protection (VCI).

Possibility of requesting specific laboratory tests, not foreseen in the applicable standard (anisotropy, salt fog, metallography, thickness elongation, among others)

Application

talk to us

If you need to know more or want a contact more suited to your needs, do not hesitate.